Mehta Steels Stockist of Rails:

Mehta Steels is one of the oldest steel trading companies in Bhilai maintaining ready stock of prime heavy Rails , Light Rails , I.U Rails & Rites Inspected t-12 Rails manufactured by SAIL , JINDAL & other renowned mills across the globe.

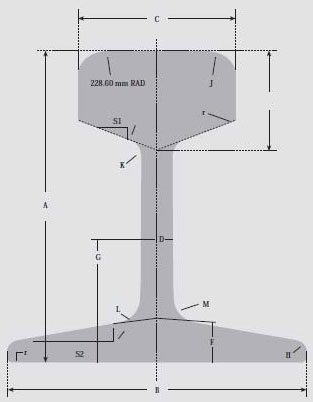

I.U.RAILS OR INDUSTRIAL USE RAILS:

The rails manufactured for the use in Industries are called industrial use Rails or IU Rails.

Following are the dimensions available with Mehta Steels of I.U. Rails:

Lengths Available: The Crane Rails are available in the 10 to 13 meters in length in ready Stock

Custom Lengths: The Custom Lenghths are considered as special orders for further details write to us at ankit.mehta@mehtasteels.com

| Profile | Weight Kg/Mtrs | Top Width (mm) | Base Width (mm) | Height Width(mm) | Web Width(mm) |

| UIC 60 | 60.34 | 72 | 150 | 172 | 18 |

| IRS 52 | 51.89 | 67 | 136 | 156 | 15.5 |

Rails

| Profile | Sectional Wt Kg/M | Standard Length(Metres) | Mill |

| R - 45 | 44.61 | 13 | Rail & Structural Mill, Bhilai |

| R - 52 | 51.89 | 13, 26, 130, 260 | Rail & Structural Mill, Bhilai |

| R - 60 | 60.34 | 13, 26, 130, 260 | Rail & Structural Mill, Bhilai |

Product nomenclature for 13 m & 26 m is “RAIL” and for 130 m & 260 m is “LONG RAIL PANEL”.

Specification

| Specifications | Grade | Application(Speed of Train Km/Hr) |

| A) Prime Quality Rails | ||

| IRS-T-12/2009 | 880 | >50 |

| Head Hardened (HH) | 1080 | >50 |

| Chromium (Cr) | 1080 | >50 |

| B) Special Rail Steel | ||

| Niobium (NB) | 880 | >50 |

| Vanidium ( VN) | 880 | >50 |

| C) Corrosion Resistant Rail Steel | ||

| Copper-Molybdenum (CM) | 880 | >50 |

| Nickel, Chromium, Copper (NC) | 880 | >50 |

| D) Industrial use | ||

| IRS-T-12-IU | 880 | <50 |

| IU | 880 | <50 |

Note:

1. Hydrogen content 1.6 ppm Max & Aluminium – .015 max.

2. Bhilai Steel Plant has taken up project to produce rail sections 68 KG & ZU1-60 (Asymmetric RAIL).

3. BSP is also developing 110 UTS quality rails.

4. Bhilai Steel Plant can also produce rails as per specifications of the union of international railways and other foreign specifications, like British standard or Japanese industrial standards if sufficient orders are available.

Chemical Composition Percentage

| Grade | C | Mn | Si | S(max) | P(max) | Al(max) | Mo(max) | Cr | V (max) | Nb(max) | 10-4%(ppm) max by mass O |

Hydrogen content in liquid steel(max) |

| 880 | 0.60-0.80 | 0.80-1.30 | 0.10-0.50 | 0.030* | 0.030* | 0.015 | - | - | - | - | - | 1.6 ppm |

| 1080 Cr | 0.60-0.80 | 0.80-1.20 | 0.50-1.10 | 0.025 | 0.025 | 0.004 | 0.20 | 0.80-1.20 | 0.20 | 20 | 1.6 ppm | |

| 1080 HH | 0.60-0.80 | 0.80-1.30 | 0.10-0.50 | 0.030* | 0.030* | 0.015 | - | - | - | - | - | 1.6 ppm |

| Special Rail Stee | ||||||||||||

| NIOBIUM (NB) | 0.60-0.80 | 0.80-1.30 | 0.10-0.50 | 0.030* | 0.030* | 0.015 | - | - | - | 0.04 | - | 1.6 ppm |

| VANADIUM (VN) | 0.60-0.80 | 0.80-1.30 | 0.10-0.50 | 0.025* | 0.030* | 0.015 | - | - | 0.20 | - | 20 | 1.6 ppm |

| Corrosion Resistant Rail Steel | ||||||||||||

| Copper-Molybdenum (CM) 0.35 | 0.60-0.80 | 0.80-1.30 | 0.10-0.50 | 0.030* | 0.030* | 0.015 | 0.2-0.3 | - | 0.25- | - | - | 1.6 ppm |

| Nickel Chromium Copper(NC) | 0.60-0.80 | 0.80-1.30 | 0.10-0.50 | 0.030* | 0.030* | 0.015 | 0.25 | 0.50-0.65 | 0.3-0.4 | 0.25- | - | 1.6 ppm |

Mechanical Properties

| UTS(MPa)(min) | Yield Strength***(MPa)(min) | Elongation% om Gauge Length-5.65 So(min) | Running Surface Hardness (BHN) |

| 880 | 460 | 10.0 | Min 260** |

| 1080 | 560 | 9.0 | 320-360 |

| 1080 | 460 | 10.0 | 340-390 |

| 880 | 540 | 10.0 | Min 260** |

| 880 | 630 | 9.0 | Min 260 |

| 880 | 460 | 10.0 | 260 |

| 880 | 520 | 10.0 | 260 |

So=Cross sectional area of tensile test piece in mm2

* 0.035 maximum for finished rail

The chemical compositions specified as above are applicable to Ladle analysis and Product Analysis. Manufacture shall ensure that chemcial composition at ladle analysis should be such

that product analysis also satisfies the requirement of chemical composition as above.

** Desirable Value.

IISCO Steel Plant

| Profile | Sectional Wt kg/m | Standard Length | Mill |

| 15 kg/m | 14.88 | 7.5 m and above | LSM |

| 30 kg/m | 29.76 | 11.5 m and above | HSM |

| 45 kg/m | 44.61 | 11.5 m and above | HS |

* Work Tested Quality only

LSM : Light Structural Mill

HSM : Heavy Structural Mill

Note : Below 11.5 m can also be supplied

Applications

| Specifications | Applications |

| 15 kg/m | Coal tub tram in colliery etc. |

| 30 kg/m | Coal tub tram in colliery etc. |

| 45 kg/m | Slow speed Railway, Light post, Charging Car, Coke Car and Coke guide car track etc. |